Understanding DC01 Galvanized Sheets: Key Insights for Professionals

Release time:

2024-09-02

DC01 galvanized sheets are an important type of coated steel that has significant relevance in the metallurgy, mining, and energy sectors. Known for their high corrosion resistance and structural integrity, DC01 galvanized sheets are produced by applying a layer of zinc to a cold-rolled steel substrate. This galvanization process not only enhances the durability of the material but also extends it

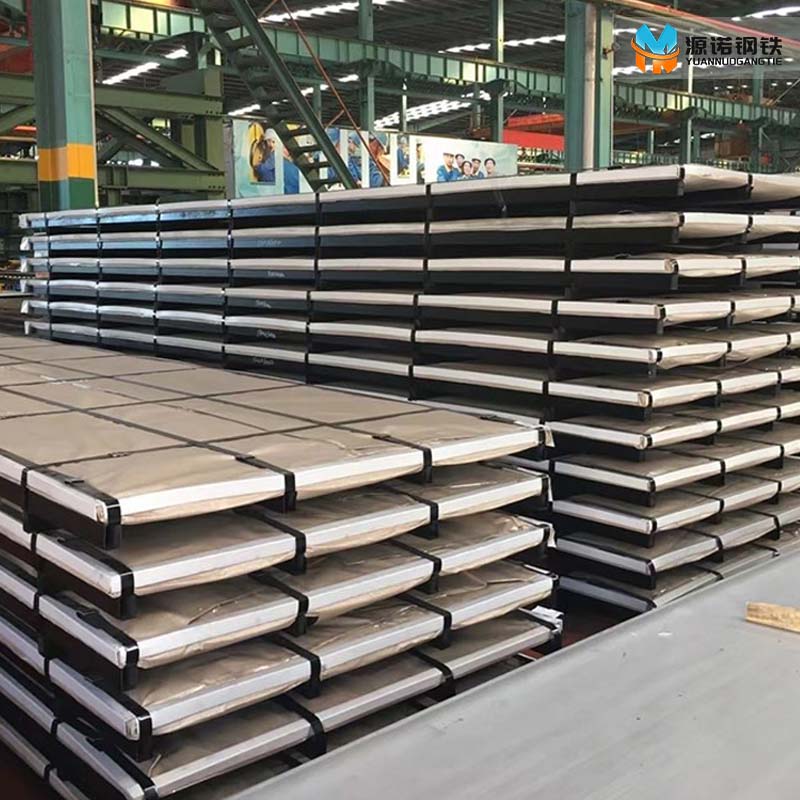

DC01 galvanized sheets are an important type of coated steel that has significant relevance in the metallurgy, mining, and energy sectors. Known for their high corrosion resistance and structural integrity, DC01 galvanized sheets are produced by applying a layer of zinc to a cold-rolled steel substrate. This galvanization process not only enhances the durability of the material but also extends its lifespan, making it a popular choice for various applications.

One of the primary benefits of using DC01 galvanized sheets is their excellent formability, which allows them to be easily shaped into various configurations for different products. This makes them particularly valuable in industries where components need to be manufactured with precision and efficiency. Additionally, the zinc coating provides superior protection against rust and other environmental factors, ensuring that the underlying steel retains its strength over time.

DC01 galvanized sheets are widely utilized in the construction industry, particularly in the production of roofing materials, wall panels, and structural components. Their lightweight nature combined with their high tensile strength allows for a wide range of architectural applications while maintaining energy efficiency. Moreover, the aesthetic appeal of galvanized surfaces makes them suitable for visible applications where appearance is a key consideration.

In the automotive sector, DC01 galvanized sheets are used extensively in the production of car bodies and components. The corrosion-resistant properties of galvanized steel help protect vehicles from the elements, extending their lifespan and reducing maintenance costs. As the automobile industry increasingly shifts towards sustainability, the recyclability of galvanized sheets also plays a crucial role in meeting environmental standards.

In terms of manufacturing processes, DC01 galvanized sheets can be produced in various thicknesses and dimensions, allowing for customized solutions tailored to specific project requirements. The advanced techniques used in the galvanization process ensure a uniform coating thickness, which is critical for achieving the desired performance characteristics.

Moreover, the DC01 designation refers to the specific grade of cold-rolled steel used in the production of these sheets, which is characterized by its excellent mechanical properties. This grade is commonly utilized in applications that require a good balance of strength and ductility.

In conclusion, DC01 galvanized sheets represent a vital material in the metallurgy and energy sectors, boasting numerous advantages such as corrosion resistance, versatility, and aesthetic appeal. Understanding the properties and applications of this material can greatly benefit professionals in related fields, enabling them to make informed decisions for their projects and enhancing their overall efficiency in operations.

Latest News

Understanding S355 Carbon Steel Plate: A Key Material in Construction

S355 Carbon Steel Plate is a structural steel grade that is widely utilized in the construction industry. It is primarily characterized by its excellent weldability, high strength, and good resistance to impact and fatigue. The “S” in S355 stands for “structural,” while the “355” indicates the minimum yield strength in megapascals (MPa). This high yield strength makes S355 an ideal choice for vari

2024-09-04

Understanding DC01 Galvanized Sheets: Key Insights for Professionals

DC01 galvanized sheets are an important type of coated steel that has significant relevance in the metallurgy, mining, and energy sectors. Known for their high corrosion resistance and structural integrity, DC01 galvanized sheets are produced by applying a layer of zinc to a cold-rolled steel substrate. This galvanization process not only enhances the durability of the material but also extends it

2024-09-02

Why 316L Stainless Steel Plate is the Ultimate Choice for Corrosion Resistance

Understanding the Superiority of 316L Stainless Steel Plate Introduction to 316L Stainless Steel 316L stainless steel is an austenitic grade of stainless steel that stands out for its enhanced corrosion resistance and mechanical properties. Often used in environments that are prone to corrosion, this alloy incorporates molybdenum, which improves its ability to resist pitting and crevice corrosion

2024-08-26