Why 316L Stainless Steel Plate is the Ultimate Choice for Corrosion Resistance

Release time:

2024-08-26

Understanding the Superiority of 316L Stainless Steel Plate Introduction to 316L Stainless Steel 316L stainless steel is an austenitic grade of stainless steel that stands out for its enhanced corrosion resistance and mechanical properties. Often used in environments that are prone to corrosion, this alloy incorporates molybdenum, which improves its ability to resist pitting and crevice corrosion

Understanding the Superiority of 316L Stainless Steel Plate

Introduction to 316L Stainless Steel

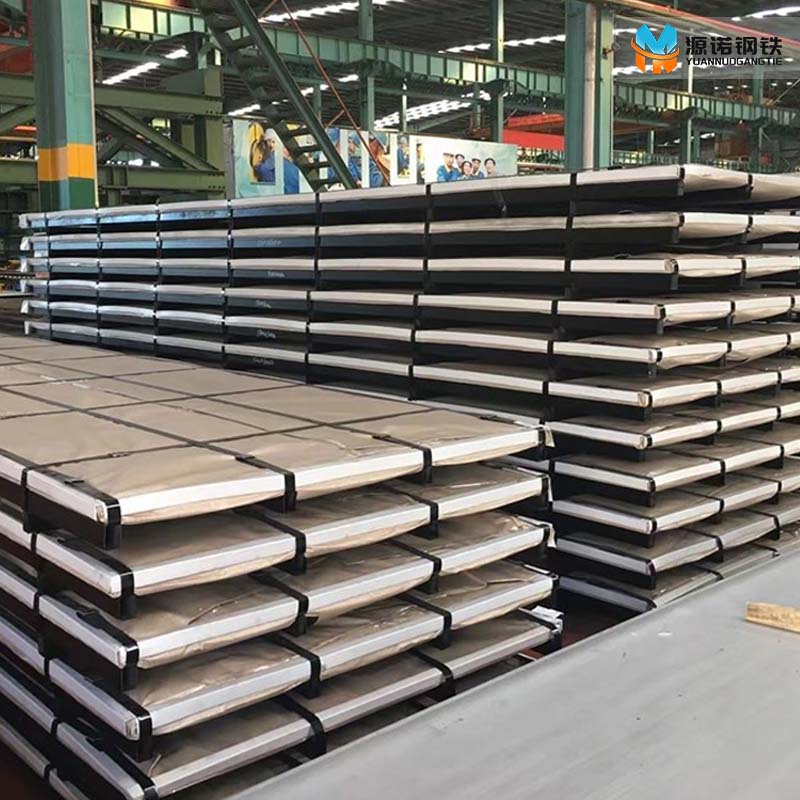

316L stainless steel is an austenitic grade of stainless steel that stands out for its enhanced corrosion resistance and mechanical properties. Often used in environments that are prone to corrosion, this alloy incorporates molybdenum, which improves its ability to resist pitting and crevice corrosion in chloride environments.

The Composition of 316L Stainless Steel

316L stainless steel primarily contains iron, chromium, nickel, and molybdenum. This unique combination of elements contributes to its impressive properties:

- Chromium (16-18%): Provides excellent oxidation resistance.

- Nickel (10-14%): Enhances ductility and toughness, especially at high temperatures.

- Molybdenum (2-3%): Improves resistance to pitting in chloride environments.

Key Properties of 316L Stainless Steel

The properties that make 316L stainless steel plate a popular choice for various industries include:

- Corrosion Resistance: The primary reason for its selection in corrosive environments.

- High-Temperature Strength: Retains strength at elevated temperatures.

- Ductility: Excellent formability allows for various shapes and sizes.

- Non-Magnetic Properties: Ideal for applications requiring non-magnetic materials.

Why Choose 316L Stainless Steel Plate for Corrosion Resistance?

In industries such as marine, chemical processing, and pharmaceuticals, the need for materials that can withstand harsh conditions is paramount. 316L stainless steel plates offer several advantages that make them the ultimate choice for corrosion resistance.

1. Exceptional Resistance to Pitting and Crevice Corrosion

Pitting corrosion occurs when small pits form on the metal surface, often due to localized breakdown of the passive layer. 316L's molybdenum content significantly reduces the likelihood of this type of corrosion.

2. Performance in Chloride Environments

Chloride ions are notorious for accelerating corrosion. 316L stainless steel's ability to resist such attacks makes it ideal for marine applications, where saltwater exposure is inevitable.

3. High-Temperature Stability

In addition to resisting corrosion, 316L stainless steel maintains its structural integrity and strength at elevated temperatures. This property is beneficial for industries that operate under extreme conditions, such as power plants and petrochemical facilities.

Applications of 316L Stainless Steel Plate

316L stainless steel plates are widely utilized across various industries due to their superior properties. Here are some of the most common applications:

1. Marine Applications

With its resistance to saltwater, 316L stainless steel is the preferred choice for boat fittings, marine hardware, and offshore platforms.

2. Chemical Processing

The chemical industry often employs 316L stainless steel for components such as reactors, heat exchangers, and storage tanks, where exposure to aggressive chemicals is commonplace.

3. Pharmaceutical and Food Industry

In environments where hygiene is critical, 316L stainless steel’s ability to resist corrosion and easy cleanability makes it suitable for pharmaceutical equipment and food processing machinery.

4. Oil and Gas Industry

316L is often used in the oil and gas sector for pipelines, valves, and pressure vessels, where both strength and corrosion resistance are essential.

Advantages of Using 316L Stainless Steel Plates

Choosing 316L stainless steel plates for your projects comes with several distinct advantages:

1. Long-Term Cost-Effectiveness

While the initial cost may be higher than other materials, the durability and low maintenance requirements of 316L stainless steel lead to lower operational costs over time.

2. Enhanced Aesthetic Appeal

316L stainless steel provides a shiny, attractive finish, making it suitable for architectural applications where appearance matters.

3. Versatile Fabrication

The ease of forming and welding 316L stainless steel allows for a wide range of applications and designs, providing flexibility for engineers and architects.

How to Maintain 316L Stainless Steel Plates

To ensure the longevity of 316L stainless steel plates, appropriate maintenance practices are essential:

1. Regular Cleaning

Frequent cleaning can prevent the buildup of contaminants that may lead to corrosion. Use mild detergents and avoid abrasive materials.

2. Avoiding Chloride Contamination

In environments where chlorides are present, it's important to use cleaning agents that do not contain chlorides and to rinse thoroughly.

3. Inspection and Monitoring

Implementing regular inspections can help identify early signs of corrosion or wear, allowing for timely interventions.

Comparing 316L Stainless Steel to Other Grades

While there are several grades of stainless steel available, 316L is often compared with 304 stainless steel, which is another popular grade:

1. Corrosion Resistance

316L offers superior corrosion resistance due to the added molybdenum, making it more suitable for marine and chemical applications.

2. Cost Considerations

304 stainless steel is generally less expensive, but it may not perform as well in highly corrosive environments.

3. High-Temperature Performance

316L maintains strength at higher temperatures compared to 304, making it the better choice for applications exposed to intense heat.

Future Trends in 316L Stainless Steel Use

As industries continue to evolve, the demand for high-performance materials such as 316L stainless steel is expected to increase. Innovations in manufacturing processes, along with growing awareness of sustainability and environmental impact, will drive further applications of this versatile alloy.

Frequently Asked Questions (FAQs)

1. What is the main difference between 316 and 316L stainless steel?

316L contains a lower carbon content than 316, enhancing its corrosion resistance and making it a better choice for welding applications.

2. Can 316L stainless steel rust?

While 316L is highly resistant to corrosion, it is not completely immune. In aggressive environments, it can still be susceptible to rust if not properly maintained.

3. Is 316L stainless steel magnetic?

No, 316L stainless steel is non-magnetic in its annealed condition, making it suitable for various applications where magnetism is a concern.

4. How is 316L stainless steel welded?

316L can be welded using various methods, including TIG and MIG welding. It is important to use filler materials that match the properties of the base metal.

5. What industries commonly use 316L stainless steel plates?

Industries such as marine, chemical processing, pharmaceuticals, and oil and gas frequently utilize 316L stainless steel due to its exceptional properties.

Conclusion

In conclusion, 316L stainless steel plate is the "ultimate choice for corrosion resistance" due to its unique composition and superior properties. Its ability to withstand harsh environments while maintaining structural integrity makes it indispensable in various industries. When considering materials for your next project, 316L stainless steel should be at the forefront of your decision-making process to ensure longevity and performance in challenging conditions. The combination of aesthetic appeal, cost-effectiveness, and versatility further solidifies its position as a top-tier material in the metallurgical and energy sectors.

Latest News

Understanding S355 Carbon Steel Plate: A Key Material in Construction

S355 Carbon Steel Plate is a structural steel grade that is widely utilized in the construction industry. It is primarily characterized by its excellent weldability, high strength, and good resistance to impact and fatigue. The “S” in S355 stands for “structural,” while the “355” indicates the minimum yield strength in megapascals (MPa). This high yield strength makes S355 an ideal choice for vari

2024-09-04

Understanding DC01 Galvanized Sheets: Key Insights for Professionals

DC01 galvanized sheets are an important type of coated steel that has significant relevance in the metallurgy, mining, and energy sectors. Known for their high corrosion resistance and structural integrity, DC01 galvanized sheets are produced by applying a layer of zinc to a cold-rolled steel substrate. This galvanization process not only enhances the durability of the material but also extends it

2024-09-02

Why 316L Stainless Steel Plate is the Ultimate Choice for Corrosion Resistance

Understanding the Superiority of 316L Stainless Steel Plate Introduction to 316L Stainless Steel 316L stainless steel is an austenitic grade of stainless steel that stands out for its enhanced corrosion resistance and mechanical properties. Often used in environments that are prone to corrosion, this alloy incorporates molybdenum, which improves its ability to resist pitting and crevice corrosion

2024-08-26