DX51D Galvanized Strip

Classification :

PRODUCT DETAILS

Galvanized strip steel is a kind of raw material called (zinc), which is used to coat the long and narrow strip steel which is cold-rolled or hot-rolled to varying degrees. Hot dip galvanizing has the advantages of even coating, strong adhesion and long service life. Complex physical and chemical reactions occur between the hot-dip galvanized steel pipe substrate and the molten plating solution, forming a corrosion resistant zinc iron alloy layer with compact structure. The alloy layer is integrated with the pure zinc layer and the strip steel matrix. Therefore, it has strong corrosion resistance.

DX51D galvanized sheet material is a non-ferrous alloy mainly composed of zinc as the matrix and other elements. The main alloy elements are aluminum, copper, magnesium, etc. Zinc alloy has low melting point, good fluidity, easy plastic processing and welding, and is resistant to atmospheric corrosion. According to the manufacturing process, it can be divided into cast zinc alloy and deformed zinc alloy. The commonly used cast zinc alloy is zinc aluminum copper magnesium alloy. Its casting process performance is good, and the cooling rate has little impact on the mechanical properties. It is mainly used to manufacture mechanical parts, toys, decorations, household appliances, etc.

Use of galvanized strip steel: strip steel is widely used in the production of welded steel pipes, as the blank of cold bending section steel, and in the manufacture of bicycle frames, rims, clamps, washers, spring blades, saw blades, hardware products and blades. The use of high hot dip galvanized strip steel is naturally associated with the application of galvanized strip steel in construction, light industry, automobile, agriculture, animal husbandry, fishery, commerce and other industries.

|

Product name: |

DX51D Galvanized Strip |

|

Place of Origin: |

China |

|

Type: |

Steel Strip |

|

Standard: |

AISI, ASTM, BS, DIN, GB, JIS ETC. |

|

Certificate: |

ISO9001 |

|

Grade: |

SPCC,SPCD,SPCE/DC01.DC02.DC03/ST12,Q195 .Etc |

|

Thickness: |

0.11-5.0mm |

|

Surface structure: |

anti-finger print /skin pass/oiled/ dry/chromated |

|

Size: |

Customized according to customer needs |

|

Tolerance: |

±1% |

|

Processing Service: |

Bending, Welding, Decoiling, Cutting, Punching, Welding |

|

Invoicing: |

by actual weight |

|

Delivery Time: |

7-15 days |

|

Technique: |

Hot Rolled Based, Cold Rolled |

|

Port: |

Tianjin Qingdao or according to your requirement |

|

Packaging Details |

in bundles, in bulk, customized packing. |

Production process:

The first stage: pickling and decontamination of the whole roll of strip steel to make the surface bright and clean.

The second stage: after pickling, it is cleaned in ammonium chloride or zinc chloride aqueous solution or mixed ammonium chloride and zinc chloride aqueous solution tank, and then sent to the hot dip tank for galvanizing.

The third stage: after the strip steel is galvanized, it is rolled up and put into storage. The galvanized layer can generally not be less than 500g/m2 according to the customer's needs, and any sample shall not be less than 480g/m2.

Post treatment of galvanized strip steel includes passivation, pre phosphating and oiling. First of all, passivation treatment should be carried out on the galvanized strip steel, which can improve the surface structure and luster of the zinc coating, improve the corrosion resistance and service life of the zinc coating, and improve the adhesion between the coating and the base metal. The chromate passivation treatment is mainly used. Some activators, such as fluoride, phosphoric acid or sulfuric acid, are added to the passivation solution to obtain a thicker chromate film after passivation. When there is fluoride in the passivation solution, the surface tension of the steel strip can be reduced, the film forming reaction can be accelerated, and the chemical polishing effect can be increased to make the passivation film fine and bright.

Our DX51D galvanized strip sets the standard for dependable corrosion protection and versatility in diverse industrial applications. Crafted from high-quality DX51D steel, this galvanized strip is meticulously processed to ensure superior performance and durability.

The galvanization process involves coating the steel with a layer of zinc, which provides exceptional resistance against corrosion, even in challenging environments. This makes our DX51D galvanized strip an ideal choice for outdoor structures, automotive components, and construction materials where longevity and reliability are paramount.

With a zinc coating that adheres firmly to the steel substrate, our strip offers robust protection against rust and oxidation. This extends the lifespan of products and structures, reducing maintenance costs and enhancing operational efficiency.

The versatility of our DX51D galvanized strip is evident across various industries. In construction, it serves as a key material for roofing, cladding, and structural supports, ensuring structural integrity and aesthetic appeal. In automotive manufacturing, its formability and durability make it essential for vehicle chassis, panels, and underbody protection.

Moreover, the strip's excellent weldability and compatibility with other materials facilitate seamless integration into manufacturing processes, optimizing production efficiency and product quality.

Committed to sustainability, our DX51D galvanized strip is produced using environmentally responsible practices, adhering to strict quality control measures and regulatory standards. This ensures that our products not only meet but exceed customer expectations for reliability and performance.

In conclusion, our DX51D galvanized strip offers unparalleled corrosion resistance, durability, and versatility, making it the preferred choice for industries demanding high-quality materials. Partner with us to discover how our galvanized strip solutions can elevate your projects with reliability and longevity in mind.

Factory Appearance

The company is headquartered in Qingdao and the factory covers an area of 20000 square meters. We have 8 advanced automatic cold forming production lines, 6 hot rolling production lines, more than 20 feeding machines, 2 environmentally friendly hot-dip galvanizing production lines, and 2 anaerobic annealing furnaces. We have invested in and constructed production lines for galvanized steel, color coated steel, seamless steel pipes, cold-rolled plates, stainless steel products, etc. in China, with an annual production capacity of 400000 tons;

Packing And Shipping

We have established long-term friendly relationships with major domestic and foreign steel mills such as Baosteel, Tiangang, Pudong Iron and Steel, and provide customers with high-quality products and services conveniently and efficiently; in addition, our company has also set up its own warehouses at major domestic ports to ensure The goods are delivered to customers as soon as possible.

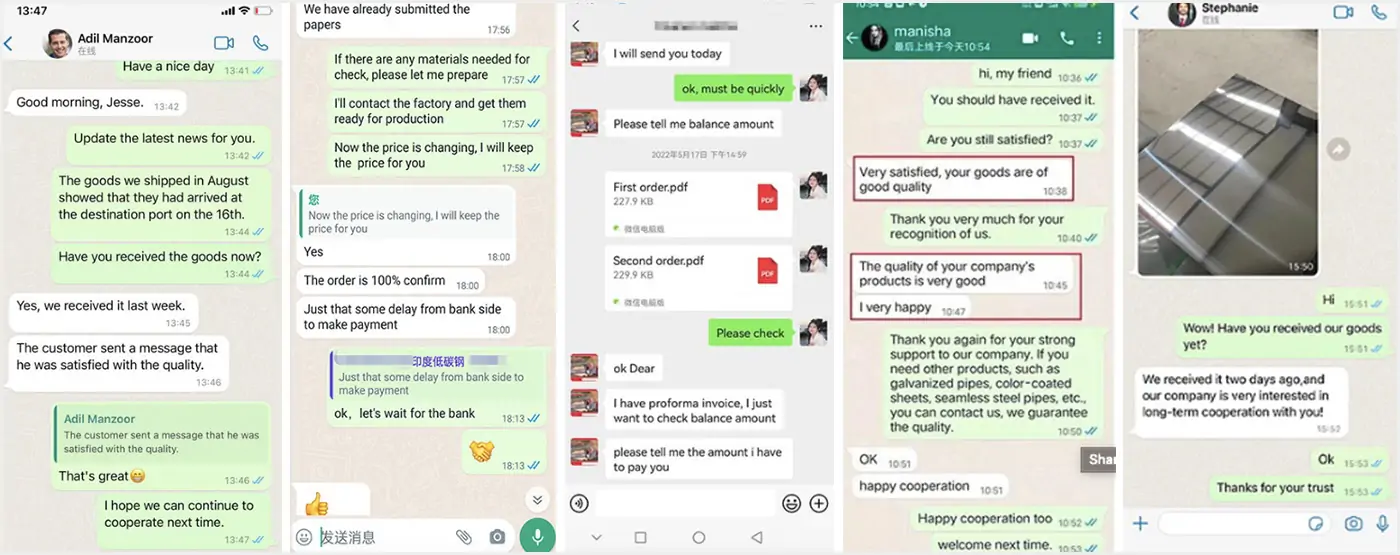

Customer communications

After more than ten years of efforts to cater to the growing needs of the international market, the company has begun to provide services to global users since 2016. As a one-stop supplier of steel and metal raw materials, we have a strong supply chain and a solid foundation.

ApplicationAreas

Based locally and serving the world, Weike Terui Steel actively promotes the high-end transformation of intelligent steel manufacturing with the concept of "quality, high-end, green, and ecological". We will continue to contribute wisdom and strength to the development of the steel industry by building a permanent benchmark enterprise in the industry!

FAQ

Q:How about the delivery time?

Q:Where are you? Can I visit you?

Q: What are the shipping ports?

Q: What certifications do your products have?

Q: What product information do I need to provide?

Q: Can you send samples?

RELATED PRODUCTS

GET A FREE QUOTE